SPINMATE

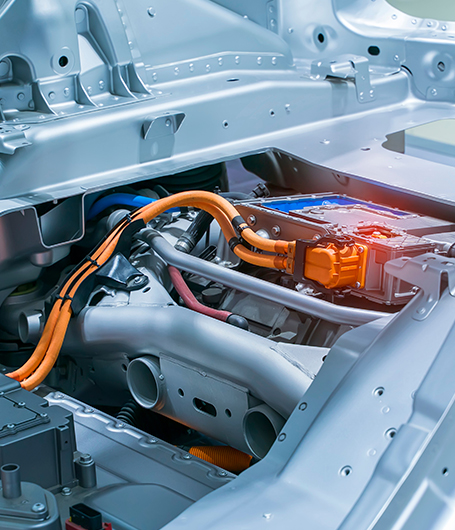

Scalable and sustainable Pilot line based on INnovative MAnufacturing TEchnologies towards the industrialization of Solid-State Batteries for the automotive sector.

One step forward to greener and cleaner energy.

SPINMATE aims to demonstrate a scalable, sustainable, safe, and cost-effective digital-driven proof-of-concept pilot line, at a Technology Readiness Level 6, as a first step towards the large-scale manufacturing of generation 4b (Gen 4b) SSB cells and module, to support the electrification of the automotive sector.

Our mission

The SPINMATE’s Gen 4b SSB cells will create a new industry value chain in Europe towards their commercialization. This new generation technology will ensure:

- Enhanced energy densities, overcoming current Li-ion batteries limitations,

- Improved safety in both solutions and workers;

- Increased sustainable mass production;

- Decreased carbon footprint and cost.

To do so, SPINMATE proposes the development and implementation of innovative and scalable manufacturing and processing solutions (notching/cutting, stacking, and sealing/packaging steps, among others).

About us

The development and deployment of new manufacturing technologies, enabling the large-scale production of Solid-State Batteries (SSBs), is crucial. Indeed, among the overarching themes to develop and produce sustainable batteries in the future, the BATTERY 2030+ roadmap considers the manufacturability as a cross cutting key area. Innovative and scalable manufacturing techniques to produce SSBs will accelerate cost reduction, energy savings and enhanced safety.

Our challenge

SPINMATE project will commit the challenge of reaching the first milestone towards the large-scale manufacturing of generation 4b (Gen 4b) SSB cells, while demonstrating the cost-effective digital-driven proof-of-concept pilot line at a TRL6 level, that will comprise industry 4.0 and 5.0 digital manufacturing concepts. By means of different digitalisation approaches, SPINMATE processing and manufacturing innovations will contribute for:

- A sustainable and competitive large-scale production of SSBs (i.e., based on market-oriented roadmap),

- The reduction of the carbon footprint, and

- Enhancement of safety along the entire value chain.

Even more

Furthermore, the SSB-based technologies developed in this project will contribute to achieving a mass electrification of the automotive sector, which has the enormous potential to reduce the global GHG emissions in 16 % by 2035.

Are you interested in collaboration?

The vision of SPINMATE project is that we believe that collaborations are essential to produce the knowledge and innovation required to address sustainability challenges. Herein, we invite all the Partners from other EU-funded projects, cost action, and platforms to contact us to make a step forward to greener and cleaner energy.

The project will have important impacts on:

Objectives

SPINMATE aims to impact on the battery industry, setting the bases for the manufacturing of the next generation of SSB cells, encompassing the development of materials for the anode, cathode and electrolyte components, the development of innovative and scalable manufacturing solutions, and the implementation of 4.0 and 5.0 concepts by means of digitalisation.

The main objectives at Spinmate are

1. Identify and define specifications and standards.

To identify and define the specifications and standards required to manufacture Gen 4b SSB cells (in particular for the EV sector), and to develop an innovative and sustainable pilot line.

To identify and define the specifications and standards required to manufacture Gen 4b SSB cells (in particular for the EV sector), and to develop an innovative and sustainable pilot line.

2. Develop, optimize and produce.

To develop, optimize and produce new solid electrolytes at large scale to be combined with Li metal-based anodes and high Nickel content oxides as cathodes, leading to enhanced energy densities

To develop, optimize and produce new solid electrolytes at large scale to be combined with Li metal-based anodes and high Nickel content oxides as cathodes, leading to enhanced energy densities

3. Create and employ digital solutions.

To create and employ digital solutions to optimise the SPINMATE manufacturing processes, focusing on the safety, performance, sustainability, and production costs, and to contribute to the positioning of Europe as leader in the industrial production of Gen 4b SSB technologies by addressing the whole value chain.

To create and employ digital solutions to optimise the SPINMATE manufacturing processes, focusing on the safety, performance, sustainability, and production costs, and to contribute to the positioning of Europe as leader in the industrial production of Gen 4b SSB technologies by addressing the whole value chain.

4. Develop indigenous and new technologies.

To develop indigenous and new technologies and improve manufacturing processes to assembly an innovative digital-driven pilot line towards the production of Gen 4b SSB cells, as well as their components, while increasing mass production costs and reducing environmental impacts.

To develop indigenous and new technologies and improve manufacturing processes to assembly an innovative digital-driven pilot line towards the production of Gen 4b SSB cells, as well as their components, while increasing mass production costs and reducing environmental impacts.

5. Design, manufacture and validate Gen4b SSB cell prototypes.

To design, manufacture and validate Gen4b SSB cell prototypes, combining advanced materials and chemistries, while demonstrating the fulfilment of the EV sector’s requirements and standards, and achieving the KPIs directly linked with the technological competitiveness of the Gen 4b technology in a cost-efficient and sustainable way.

To design, manufacture and validate Gen4b SSB cell prototypes, combining advanced materials and chemistries, while demonstrating the fulfilment of the EV sector’s requirements and standards, and achieving the KPIs directly linked with the technological competitiveness of the Gen 4b technology in a cost-efficient and sustainable way.

6. Create and establish a wide knowledge portfolio.

To create and establish a wide knowledge portfolio, engaging the key stakeholders and end users to expand the project’s scope towards new market opportunities to maximise its impact.

To create and establish a wide knowledge portfolio, engaging the key stakeholders and end users to expand the project’s scope towards new market opportunities to maximise its impact.